TAS POLYMERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TAS POLYMERS

Platinum Cured Silicone Transparent Tube Which Complies With Usp

TAS Polymers Silicone transparent tubing is highly flexible and hydrophobic in nature. We are manufacturing our FDA grade silicone transparent tubing using 100% pure silicone rubber, Platinum Cured Translucent Silicone Tubings suitable for food contact, peristaltic pumps etc., Generally used to carry liquids and powders within the food processing and pharmaceutical industries.

Odorless and can withstand many drugs/chemicals and prevents bacterial growth with Non-toxic, Excellent heat resistant from -50°C to + 200°C.

Platinum Cured Silicone Braided Hose Which Complies With Usp Class

TAS Polymers manufacturers Types of silicone transparent Braided hoses of different types like - Reinforced with polyester with single ply and double ply, Reinforced with SS 316 Helical wire, Reinforced with polyester and SS316 Helical wire, Reinforced with PTFE lined and SS304 Helical wire, etc., with end fitting or without fittings.

These Braided Hoses are available in Platinum cured and Peroxide grade which allows excellent bend Radii and permits installation in restricted spaces without impeding flow, Sterilized by steam, dry heat, ethylene oxide (ET), Unaffected by steam and most water soluble materials, Resists oxidation, ozone and radiation, Non reactive to body tissue and fluid, Does not support Bacterial growth, Temperature resistant range from –80°C to 250°C (-110°F to 480°F).

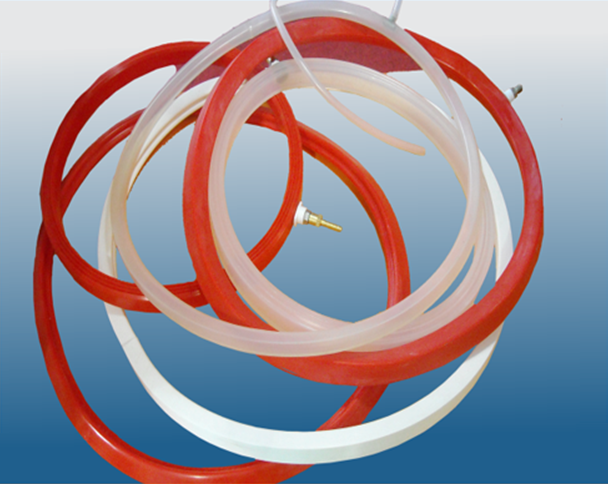

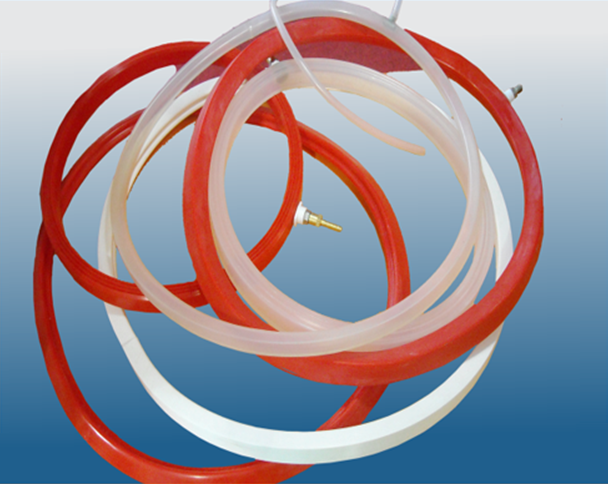

Inflatable Gaskets For Fbd And Fbp And Fbc Inflatable Gaskets

TAS Polymers manufactures FBD seal gaskets are used in sealing applications. These silicone sealing gaskets will prevent the gas/liquid leakage and functions like a cycle tube, when inflated, it seals the passage of the groove and ensures proper sealing. Gives Tolerance and Pressure, Leak

Gives Tolerance and Pressure, Leak proof at joint and nozzle, Generally used by Fluid bed dryers in pharmaceutical applications, Powder and bulk solid handling machinery, Food processing equipment, Door seal in various applications etc.,

Silicone Neoprene Viton And Ptfe Rubber Sheets

TAS Polymers offers durable Rubber Sheet made up of Silicon, Viton, PTFE in compliance with FDA 21CFR 177.2600 requirements with quality product. And high performance sheet range suitable for continuous use at temperatures from -80°C to + 250°C and Chemically extremely stable and suitable for use with many acids and alkalis. No harmful toxic or physiological effects. Resistant to ozone, oxidation, ultraviolet light, corona discharge, cosmic radiation and weathering in general.

O Rings (Silicone And Fkm Viton And Ptfe Teflon)

TAS Polymers manufacturers the O Rings with high resistance to temperature, chemicals, oil, minerals, oxygen and many organic solvents. They possess excellent permeability and high compression set resistance, Tensile strength %, Elongation %. With low gas permeability and complies to FDA standards for non toxicity, and range from Silicone, EPDM, Viton, , Teflon. Neoprene, Nitrile etc., with transparent, red, orange, milky white, green etc., with leak proof solutions in various industrial equipments

Tri Clover (T And C) Gaskets With Collar Or Without Collar

Gaskets With Collar Or Without Collar 62380.jpg)

Tri-Clamp Gaskets are available Silicone Platinum cured and Peroxide grade,FKM /viton, EPDM, PTFE/Teflon which Complies to FDA 21 CFR 177.2600 & USP Class VI 100% with collar for better‘ grip and also without collar and are used as leak proof solutions in various industrial equipments

Available in Red, White, Black & Transparent colours

Silicone Customized Products

Apart from this TAS Polymers manufacturers the customized products like Rubber Expansions/Compression Bellows, Diaphragms, Shifter/Centrifuge/RMG Gaskets etc, with high resistance to temperature, chemicals, oil, minerals, oxygen and many organic solvents. They possess excellent permeability and high compression set resistance, Tensile strength %, Elongation %, with low gas permeability and complies to FDA standards for non toxicity, with quality polymers from Silicone, EPDM, Viton, Neoprene, Nitrile etc., with transparent, red, orange, milky white, green etc., with leak proof solutions in various industrial equipments

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

Gaskets With Collar Or Without Collar 62380.jpg)